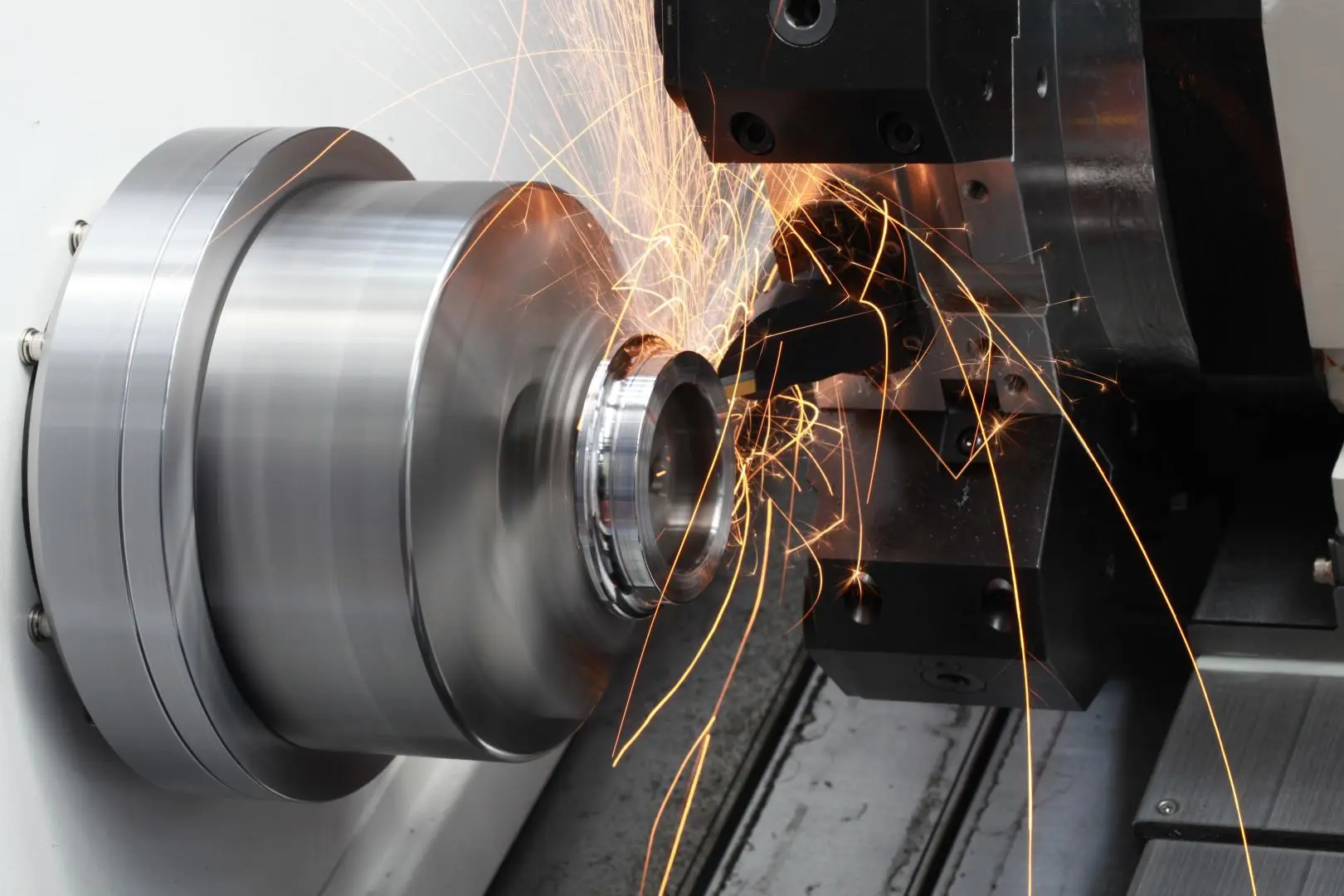

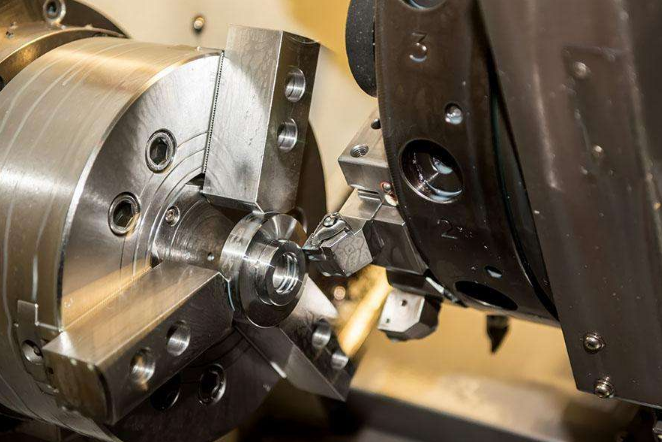

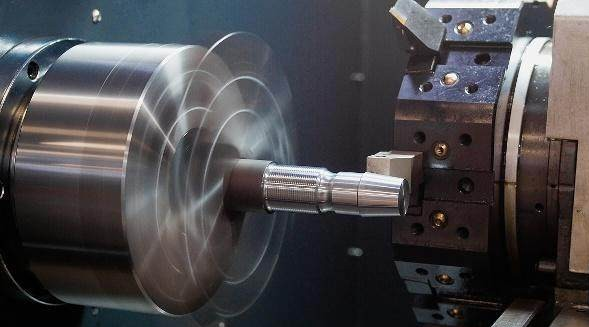

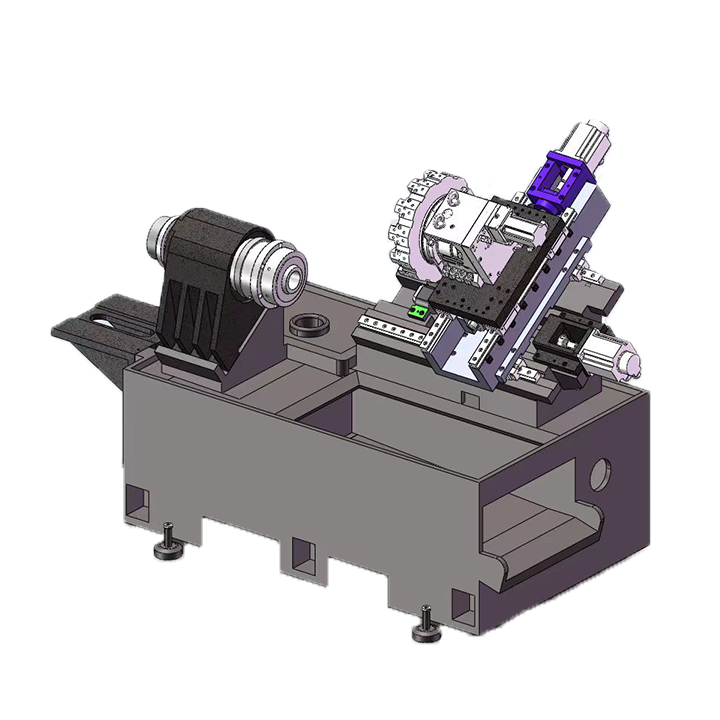

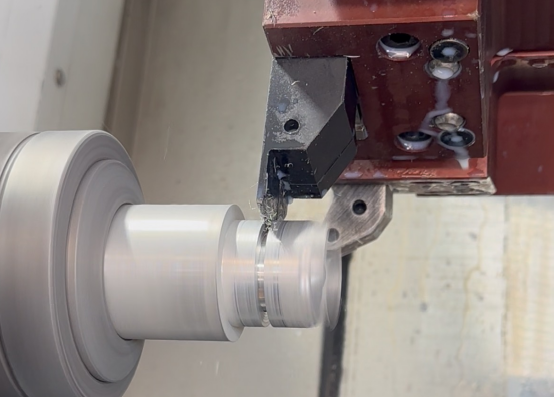

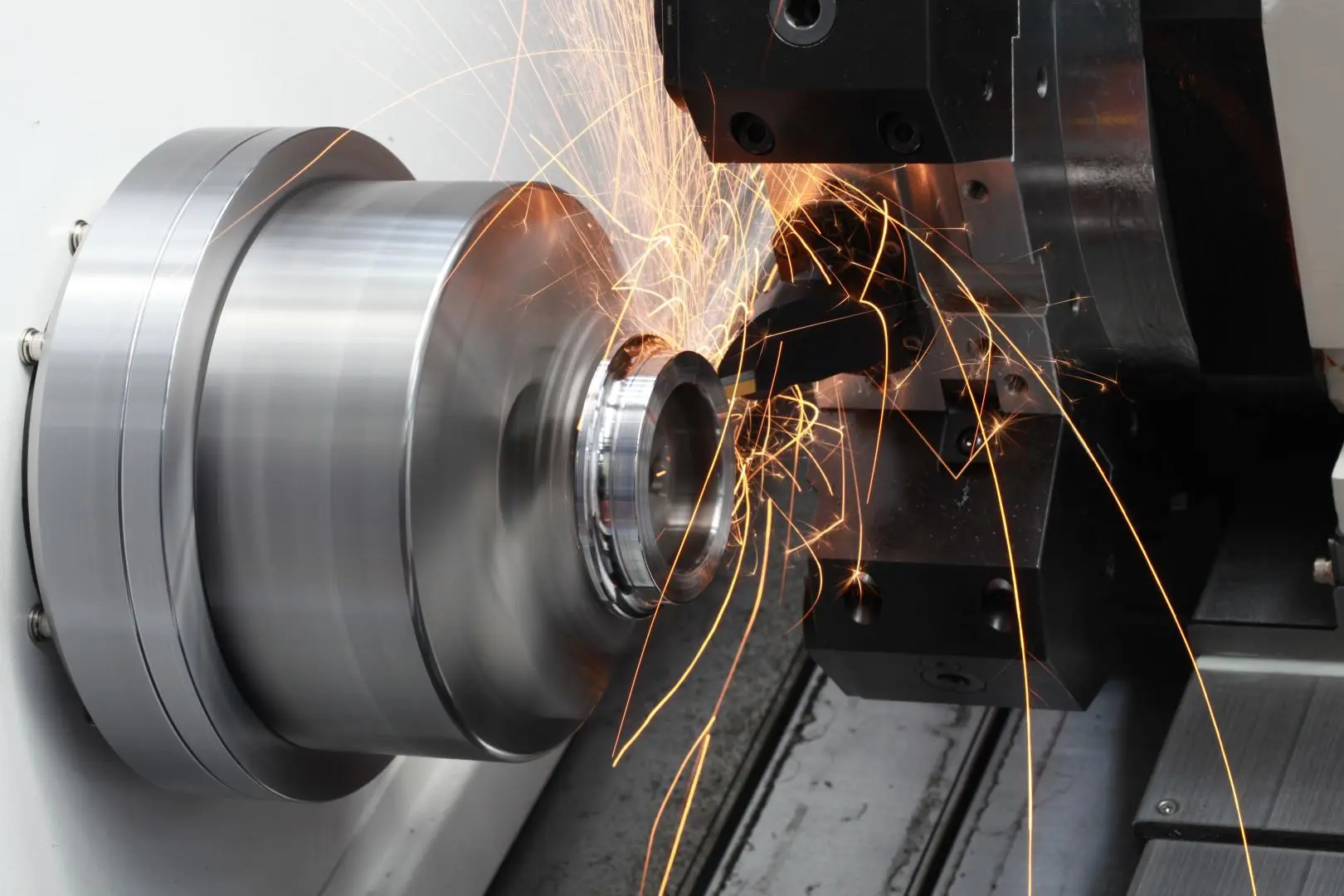

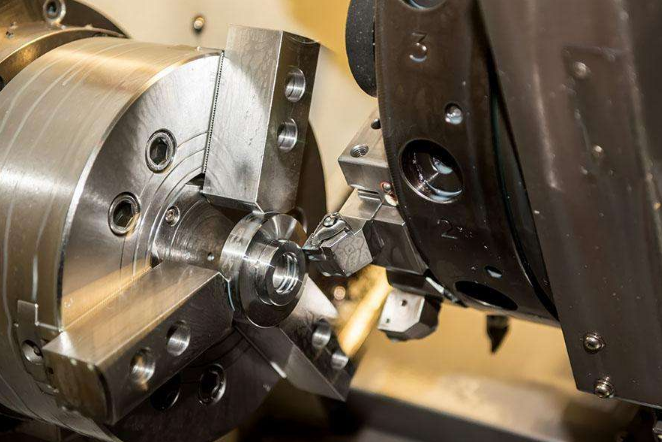

Twin Spindle CNC Lathe is an advanced CNC turning machine equipped with two spindles—a main spindle and a sub-spindle. The Twin Spindle CNC Lathe (also called a dual-spindle CNC lathe) is an advanced CNC turning machine equipped with two spindles—a main spindle and a sub-spindle—designed to complete both the front-side and back-side machining of a workpiece in one setup. This configuration eliminates manual part repositioning, significantly improving: Cycle time Machining accuracy Production automation Operator efficiency Twin spindle lathes are heavily used in medium-to-high volume production environments where precision and throughput are essential. Key Features and Functions 1. Two Spindle Structure Main Spindle Performs primary turning operations on the first side of the part. Sub-Spindle Receives the part from the main spindle Completes secondary operations (back-facing, tapping, drilling, grooving, etc.) Eliminates the need for secondary machines This enables complete machining in one cycle. 2. Part Transfer Function The machine automatically transfers the workpiece from the main spindle to the sub-spindle using: Programmable spindle synchronization Servo-driven transfer Chuck-to-chuck alignment This ensures perfect concentricity between sides. 3. High-Productivity Automation Twin spindle machines are compatible with: Bar feeders Gantry loaders Robotic arms Inline production cells Perfect for continuous, unattended machining. 4. Multi-Axis Configurations Common configurations include: Twin spindle, single turret Twin spindle, twin turret Twin spindle with Y-axis Twin spindle with live tooling / milling capability The more turrets and axes, the higher the simultaneous machining capability. A Dual Spindle Lathe significantly improves machining productivity by completing both sides of a component in one cycle. With dual spindles, automated part transfer, optional dual turrets, and compatibility with robotic loaders, it is a top choice for demanding industrial production environments.

What types of parts can be made on a Gang Type CNC Lathe?-

What types of parts can be made on a Gang Type CNC Lathe?

Our Gang Type CNC Lathe is a versatile machine widely used in precision machining industries. Unlike traditional lathes, it features a gang tool post that holds multiple cutting tools simultaneously, allowing for high-speed, multi-operation machini...

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!-

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!

As a core component in mechanical transmission systems, gears are present in almost every mechanical device we encounter in daily life. From automotive gearboxes to power tools, from clocks to industrial robots, gears are ubiquitous. Let’s uncover si...

Happy Year of the Horse: A Warm Celebration for All-

Happy Year of the Horse: A Warm Celebration for All

The festive tempo across the globe gradually settles down, and the joyful atmosphere of the Lunar New Year is already wafting around. As a China-based intelligent manufacturer specializing in CNC machine tool exports, we are delighted to celebrate th...

Is the thread turning always resulting in broken teeth? Avoid these 4 wrong actions!-

Is the thread turning always resulting in broken teeth? Avoid these 4 wrong actions!

Thread turning is a common process in CNC machining, but many operators often encounter thread defects (such as rough thread surfaces, inaccurate dimensions, chipped teeth, etc.) during processing. In fact, these issues are often caused by several co...

The Core Differences Between Power Turrets and Servo Turrets for CNC Machine Tools-

The Core Differences Between Power Turrets and Servo Turrets for CNC Machine Tools

Among the core components of a CNC lathe, the tool turret serves as a key device for tool switching and machining execution, and its performance directly determines the machining capability, precision, and applicable scenarios of the machine tool. Po...

Analysis of Differences in Adaptation Between Syntec Bus and Motor Drives for Weichuang, Keteng and Yuhai Motors-

Analysis of Differences in Adaptation Between Syntec Bus and Motor Drives for Weichuang, Keteng and Yuhai Motors

In the motion control of CNC machine tools, the compatibility between the bus and the motor drive directly affects equipment stability, machining accuracy, and costs. There are significant performance differences when Syntec bus is paired with drives...

In addition to turning-milling compound machining, what are the other common machining methods?-

In addition to turning-milling compound machining, what are the other common machining methods?

On the precise stage of modern manufacturing, CNC machine tools can be called industrial magicians. With their precise and efficient processing capabilities, they produce complex parts for various industries. When it comes to the processing methods o...

What are the advantages of slant-bed lathes?-

What are the advantages of slant-bed lathes?

Slant-bed lathes have emerged prominently among various types of lathes due to their unique design and excellent performance, gaining favor from processing enterprises. Let's delve into the advantages of slant-bed lathes. 您的浏览器不支持 video 标签。 Excellen...

Correct Method for Removing the Cutting Tool-

Correct Method for Removing the Cutting Tool

Life-Saving Guide for Removing CNC Lathe Tools: One Wrong Step Ruins the Tool, Three Wrong Steps Damage the Machine! An operator in a factory tried to remove a tool without relieving pressure, causing the hydraulic cylinder to burst—shrapnel even pi...

The problem of synchronization between the spindle and feed in thread misalignment during thread processing-

The problem of synchronization between the spindle and feed in thread misalignment during thread processing

Why is synchronization so crucial? The synchronization between the spindle and feed is vital for thread machining. We know that threads are formed by the rotation of the spindle driving the workpiece to rotate, while the feed system drives the tool ...

What is the difference between turret and gang tooling?-

What is the difference between turret and gang tooling?

In CNC turning centers , turret tooling and gang tooling represent two different tool-holding and tool-changing systems. Each offers unique advantages depending on the production requirements, part size, and machining complexity. 1. Tool Arrangement...

What industries use Gang Type CNC Lathes?-

What industries use Gang Type CNC Lathes?

Growing Demand for Gang-Type CNC Lathes as Precision Manufacturing Accelerates Across Key Industries As global manufacturing continues shifting toward high-precision, high-efficiency production, demand for gang-type CNC lathes is rapidly increasing a...

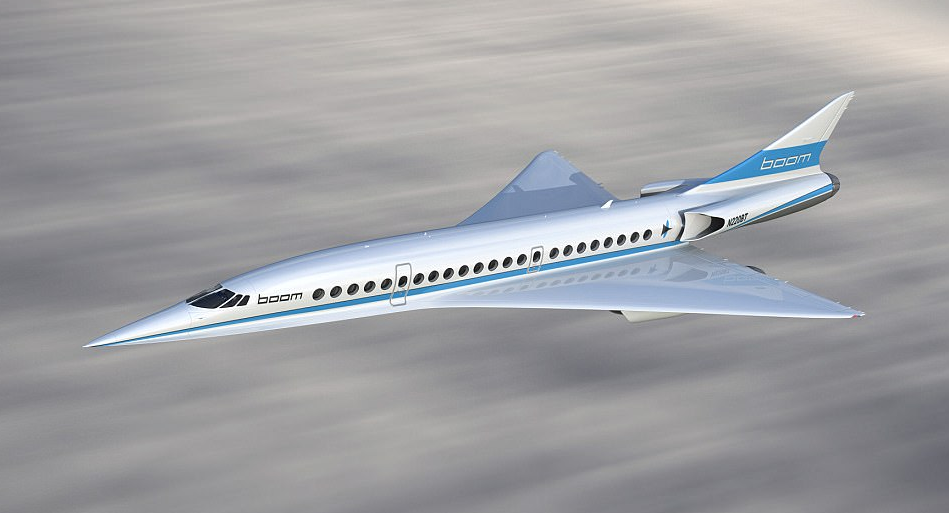

Why do airplanes use millions of rivets for assembly instead of welding?-

Why do airplanes use millions of rivets for assembly instead of welding?

When we look at an aircraft up close, we will notice that its fuselage is covered with countless rivets, just like buttons on a metal coat. According to data, a medium-sized airliner such as the C919 has over one million rivets all over its body. Why...

How to Select Appropriate Programming Software for CNC Machine Tools?-

How to Select Appropriate Programming Software for CNC Machine Tools?

With the continuous development of technology, modern numerical control (NC) programming has gradually shifted from pure manual programming to relying on professional programming software. In the processing of numerically controlled machine tools, pr...

Tips for Cutting Tool Inventory Management: Store Them Like This to Extend Service Life by 2 More Years!-

Tips for Cutting Tool Inventory Management: Store Them Like This to Extend Service Life by 2 More Years!

In the field of CNC lathe machining, cutting tools are key elements ensuring production accuracy and efficiency. However, many enterprises and processing workshops often neglect the inventory management of cutting tools, leading to premature wear, ru...

The problem of synchronization between the spindle and feed in thread misalignment during thread processing-

The problem of synchronization between the spindle and feed in thread misalignment during thread processing

Why is synchronization so crucial? The synchronization between the spindle and feed is vital for thread machining. We know that threads are formed by the rotation of the spindle driving the workpiece to rotate, while the feed system drives the tool ...

What's the difference between turning tools, milling cutters, and drill bits? 90% of newbies choose the wrong one!-

What's the difference between turning tools, milling cutters, and drill bits? 90% of newbies choose the wrong one!

In the world of metalworking, turning tools, milling cutters, and drill bits are the most basic and commonly used tools. However, for newbies who have just entered the industry, they often get them mixed up. Choosing the wrong tool not only affects t...

The Hazards of Poor Grounding of Machine Tools to Electrical Systems and Rectification Measures-

The Hazards of Poor Grounding of Machine Tools to Electrical Systems and Rectification Measures

In a certain factory, CNC machine tools frequently experienced unexplained shutdowns, program malfunctions, and even accidental drive burnout, forcing production lines to halt and causing heavy losses. After repeated troubleshooting failed to identif...

Beijing Jingdiao Completes Strategic Financing of Over 1 Billion RMB-

Beijing Jingdiao Completes Strategic Financing of Over 1 Billion RMB

Recently, the domestic precision CNC machine tool sector has witnessed a groundbreaking development: Beijing Jingdiao Technology Group Co., Ltd. (hereinafter referred to as "Beijing Jingdiao") has secured over RMB 1 billion in strategic financing. Th...

Does the CNC program stop midway during operation? It may be an issue with the M-code settings-

Does the CNC program stop midway during operation? It may be an issue with the M-code settings

In the precise world of CNC machining, the accurate execution of every instruction is crucial to ensuring smooth production. However, many practitioners have encountered such troubles: the CNC program suddenly stops in the middle of operation, disrup...

What types of parts can be made on a Gang Type CNC Lathe?-

What types of parts can be made on a Gang Type CNC Lathe?

Our Gang Type CNC Lathe is a versatile machine widely used in precision machining industries. Unlike traditional lathes, it features a gang tool post that holds multiple cutting tools simultaneously, allowing for high-speed, multi-operation machini...

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!-

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!

As a core component in mechanical transmission systems, gears are present in almost every mechanical device we encounter in daily life. From automotive gearboxes to power tools, from clocks to industrial robots, gears are ubiquitous. Let’s uncover si...

Happy Year of the Horse: A Warm Celebration for All-

Happy Year of the Horse: A Warm Celebration for All

The festive tempo across the globe gradually settles down, and the joyful atmosphere of the Lunar New Year is already wafting around. As a China-based intelligent manufacturer specializing in CNC machine tool exports, we are delighted to celebrate th...

Is the thread turning always resulting in broken teeth? Avoid these 4 wrong actions!-

Is the thread turning always resulting in broken teeth? Avoid these 4 wrong actions!

Thread turning is a common process in CNC machining, but many operators often encounter thread defects (such as rough thread surfaces, inaccurate dimensions, chipped teeth, etc.) during processing. In fact, these issues are often caused by several co...